Capacities summary

| PROPERTIES | SYSTEM MODEL | ||

|---|---|---|---|

| Electronic | Mechanic | ||

| EzCalipre3D Tram Bar | 300C+/695F | 300MC | |

| 3D measuring (with length, width and height readings) | X | X | – |

| 2D measuring (with Point-to-Point distance) | X | – | X |

| Insensitive to environment disturbance (sounds, light, air contitioning) | X | X | X |

| Accurate and reliable upperbody measuring | X | X | X |

| Accurate and reliable chassis measuring | X | X | X |

| No extra accessories needed for upperbody measuring | X | X | X |

| Number of points showing at the same time (upperbody + chassis) | 1 | 2 + 6 1) | 1 |

| Can quickly measure chassis points and upperbody points in mixed order | X 2) | X | X |

| Can measure extra high vehicles | X | o | X |

| Can measure extra long vehicles | X | o | X |

| Cross measuring function | X | – | X |

| Photographs for locating measuring points | X | X | X |

| Datasheets available on paper | – | o | – |

| Number of measuring points in the datasheet (upperbody + chassis) | 30 + 36 | 30 + 36 | 30 + 36 |

| Updates for datasheets available from Internet | X | X | X |

| Before and after repair reports | X | X 3) | X 3) |

| Visualises repair progress during pulling | – | X | – |

| Can be used on lift set/lift post | X | | | X |

| Wireless communication to computer | X | – | – |

| Choose measuring head settings in the device’s operation panel | X | – | – |

| Save measuring points in the device’s operation panel | X | – | – |

| “Battery low” warning | X | – | – |

| X | Standard function |

| | | Available after upgrade |

| * | Available as accessory |

| o | Available on special order |

| – | This feature is not available |

1) With 695F measuring arch 2 points can be measured simultaneously (upperbody). In the chassis up to 6** points can be measured at the same time with bridges I-III.

2) Additional Tracker module is required to utilize underbody calibration in upperbody. Without Tracker unit system must be recalibrated.

3) With mechanical system the measuring results must be typed manually in the computer to get a printed report (a PC is required for using the software).

**) Bridges No. I and II measure symmetrical vehicle widths. Bridge No. III measures widths that can be different on the left and on the right side of the vehicle.

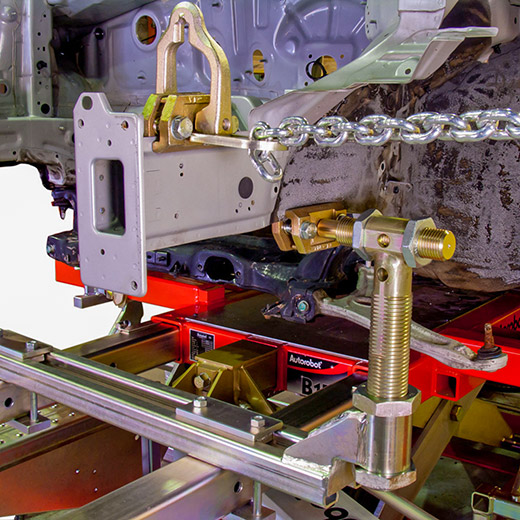

Autorobot’s strengths

Ergonomic work enables faster and more efficient working methods that do not strain the technician.

Autorobot Finland’s decades-long trend of innovative work has been positively recognized and awarded with many national and international prizes.

Speed and high product quality of car body repair are characteristics to all our equipment. Efficient car body and chassis work shortens the turnaround time of repair jobs.

With new generation remote-controlled equipment the functions can be controlled near the work station.